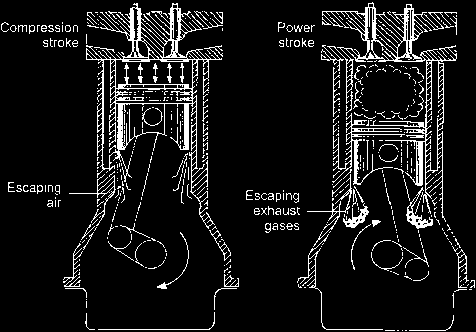

I just finished another pre-purchase mechanical survey, and doing a blow-by test on the engines is part of our investigation. Each time, people always ask ‘What is blow-by?’

Basically ‘blow-by’ is the air and combustion gases from the cylinder, on top of the piston that escape past the piston rings into the crankcase. No engine will have perfect sealing rings, though as the rings, and cylinder wear the blow-by will increase giving an indication to the engine health.

Blow-by not only is a tell-tail on the engine health, but there are several negative effects. Blow-by not only pressurizes the crankcase but also introduces combustion gases that contain unburned fuel, particulate matter, and oxides of nitrogen emissions. They also create condensation due to the temperature differential of combustion gases and the crankcase.

Blow-by tears the oil from the piston and rings. At first it vaporizes and then it becomes an aerosol, which you see as a film or fumes around the crankcase vent tube. When mixed with engine oil, blow-by produces sludge and acids that attack all engine parts. The unburned fuel dilutes the lubricity and viscosity of the engine oil, attacking engine bearings, the valve train, and cylinder walls.

When the blow-by becomes more than the crankcase ventilation can handle, other problems start to happen, from blown out crankshaft main seals, to an engine ‘run away’, where the oil vapor becomes a fuel for the diesel engine and it then starts running on it’s own engine ‘oil fuel’, with no ‘standard way’ to shut it down – a run away engine is rare, but extremely dangerous.

Power Point presentation from the Mining Diesel Emissions Conference October 7-9th, 2014 – Retrofit Crankcase Ventilation for Diesel Engines: https://mdec.ca/2014/S6P2-Stekar.pdf

Controlling Blowby in Diesel Engines by Ray Bohacz, 3/20/2019 Successful Farming: https://www.agriculture.com/machinery/repair-maintenance/controlling-blowby-in-diesel-engines

Causes of Diesel Engine Oil Blow By by Tony Oldhand – It Still Runs https://itstillruns.com/causes-diesel-engine-oil-blow-6930901.html

∞