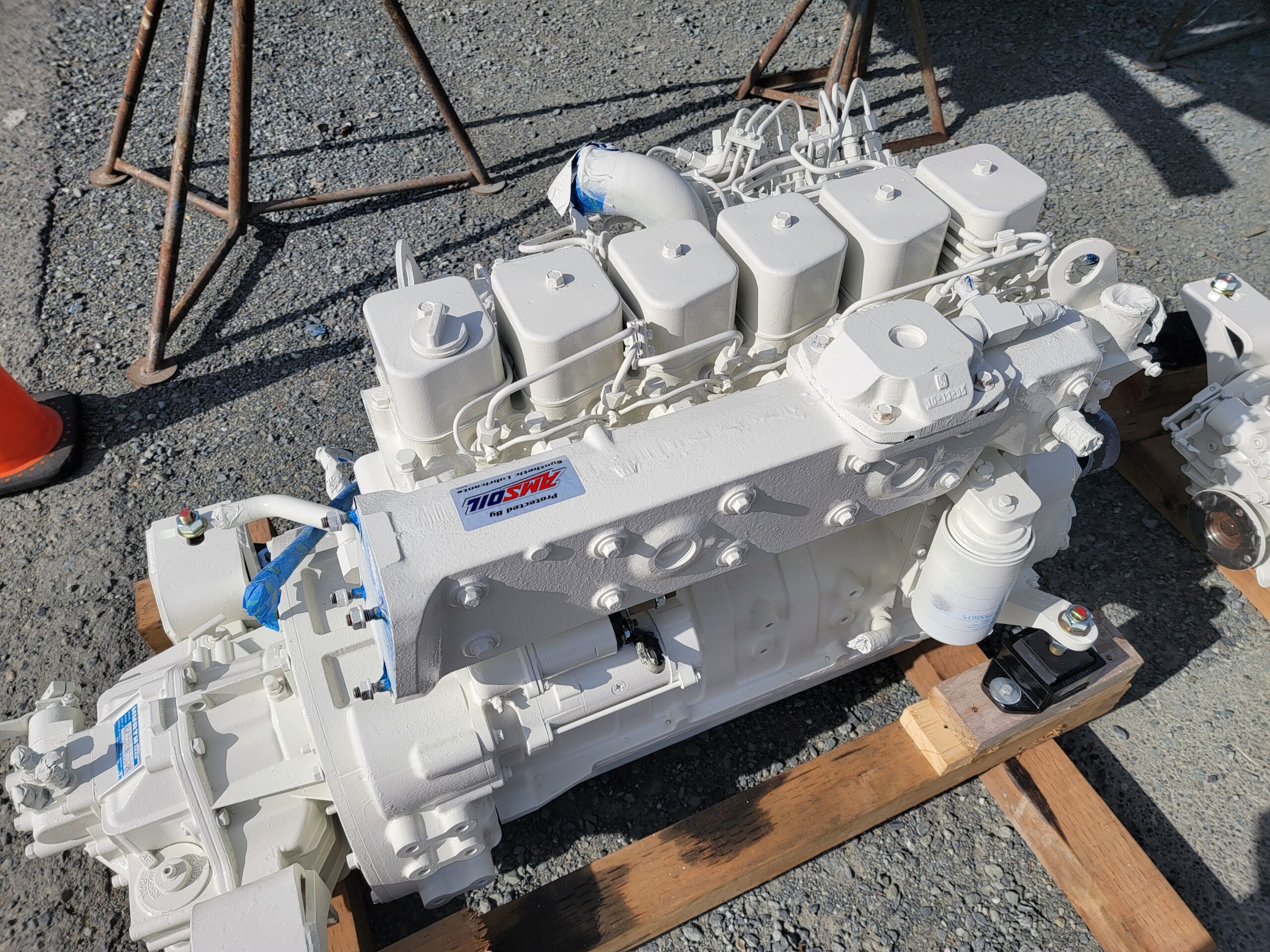

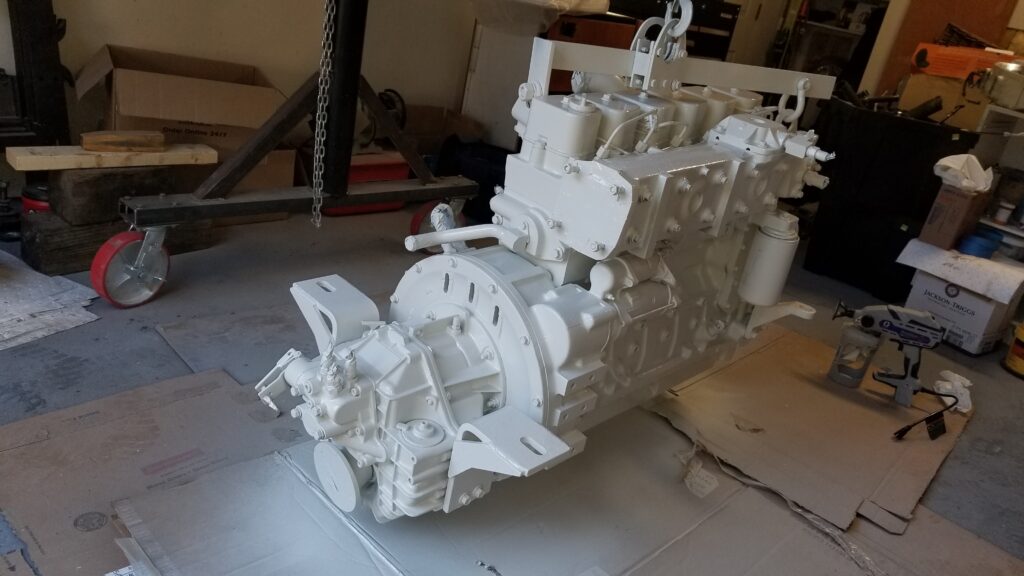

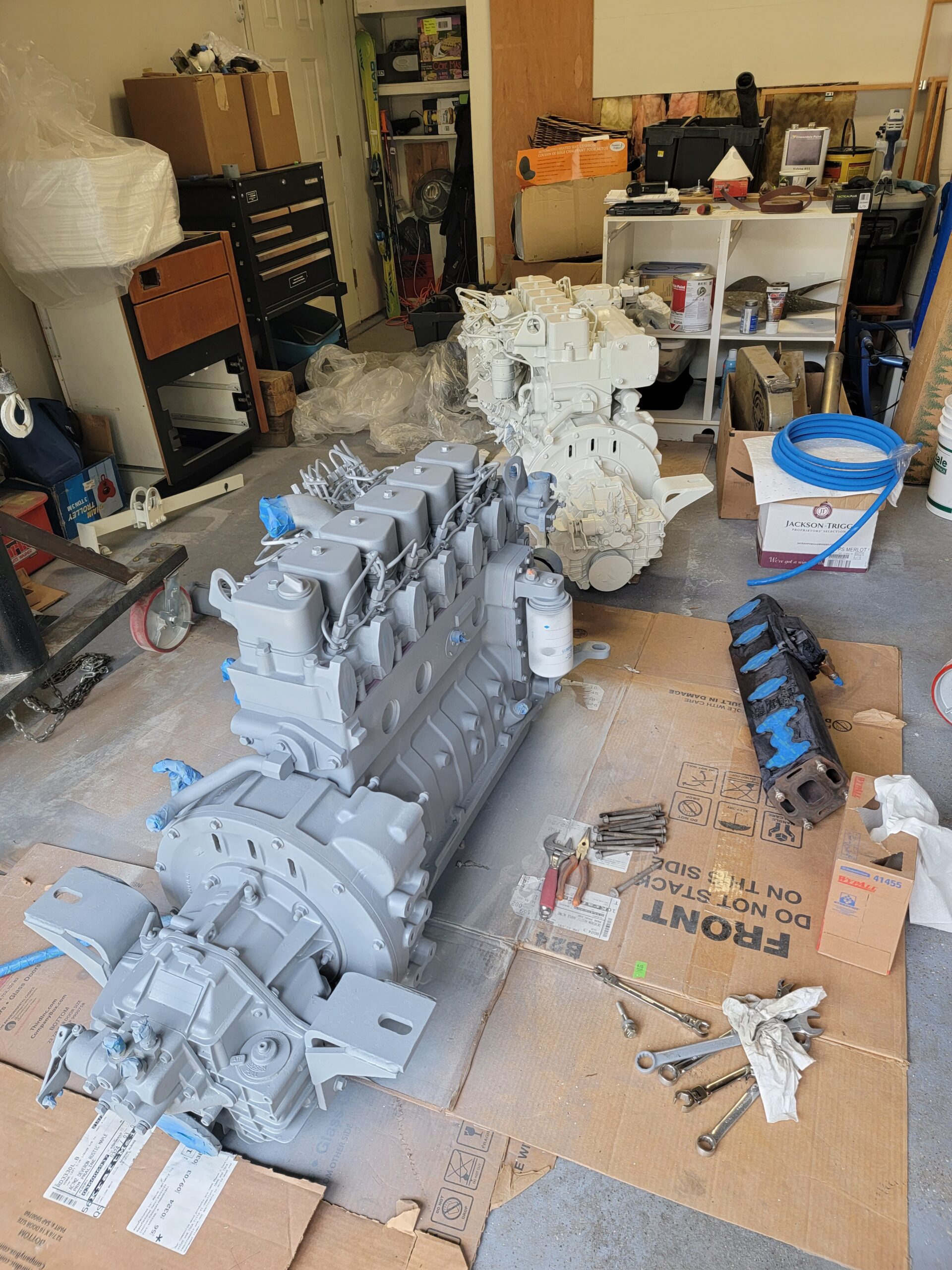

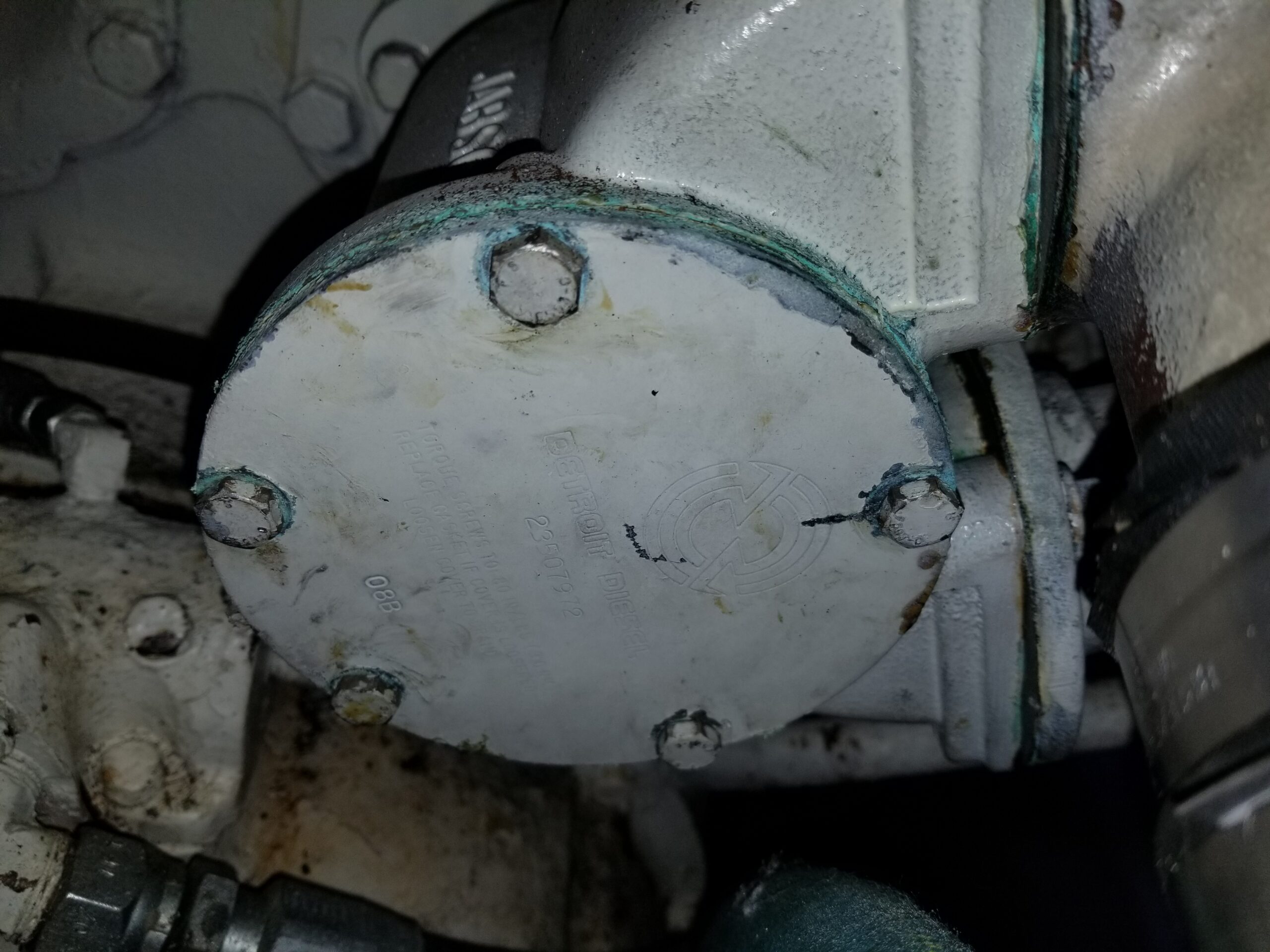

Cummins 6BTA5.9 professionally rebuilt, higher end components than OEM, new camshafts for more power, and better fuel efficiency.. Balanced, Magnafluxed (Blueprinted)! This is definitely not your average Cummins 5.9 anymore!

There is something special about when a client takes their newly powered boat out, running it up and having this huge smile, and saying:

“This is the fastest this boat has ever gone!”

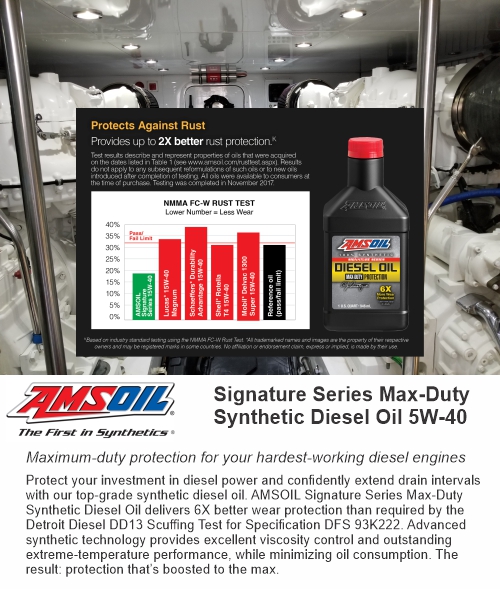

Complete Amsoil treatment throughout – Amsoil Assembly lube, Amsoil break-in lubrication. Amsoil Signature Series Max-Duty 15w-40 Diesel oil, and Amsoil Filters, to give these engines the best of the best! Even the Coolant is Amsoil’s amazing Low-Toxicity, Bio-degradable coolant with specs even the US Military uses!